The food manufacturing industry is continually seeking innovative ways to ensure product quality and safety. Enter computer vision, a cutting-edge technology that's revolutionizing how manufacturers perform quality inspections and manage production processes. From automated defect detection to streamlining visual tasks, computer vision is setting a new standard in food quality control.

Introduction to Computer Vision in Food Quality Inspection

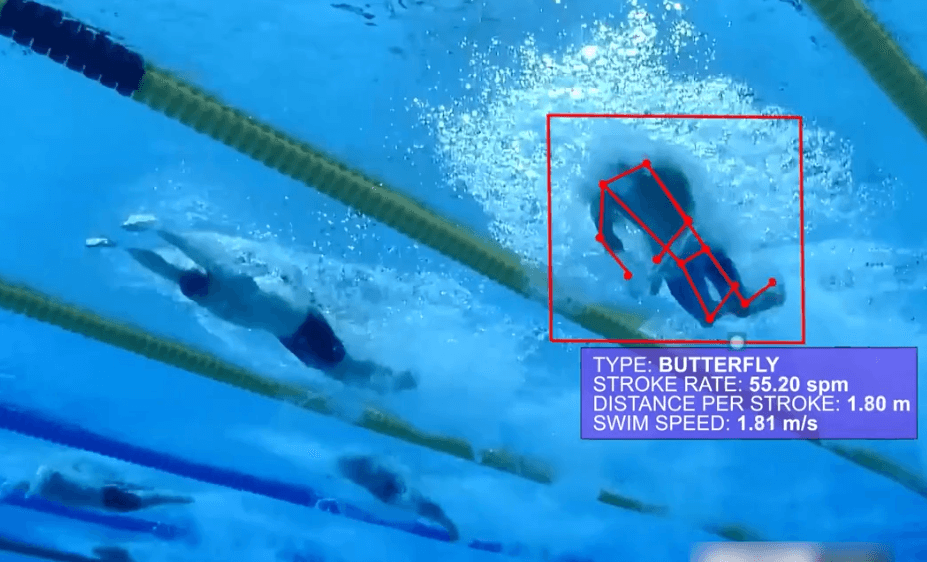

Before delving into the benefits, let's briefly explore what computer vision is and how it's applied in food quality inspection. Computer vision (CV) is a field of artificial intelligence (AI) that enables computers to interpret and make decisions based on visual data. In food manufacturing, CV technology uses cameras and sensors to analyze products in real-time, offering precise insights that were previously unattainable through manual inspection.

Enhancing Food Quality Control with Computer Vision AI

In the food manufacturing industry, ensuring product quality is paramount. Traditionally, manual inspection processes have been time-consuming and prone to human error. However, with the advent of computer vision, manufacturers can now automate quality inspection tasks, ensuring consistent and reliable results.

Benefits for Food Manufacturers:

Automated Defect Detection: Quickly identify and reject defective products. Computer vision systems can detect defects such as discoloration, contamination, and shape irregularities with high precision, ensuring only high-quality products reach consumers.

Consistent Quality: Maintain uniform product standards. CV technology can monitor production lines in real-time, providing immediate feedback and adjustments to maintain consistent quality.

Speed and Efficiency: Accelerate inspection processes. Automated inspections are significantly faster than manual ones, increasing the overall throughput of production lines.

This data-driven approach helps manufacturers maintain high standards of quality, reduce waste, and optimize production efficiency.

Streamlining Visual Tasks in Production Processes

Visual inspections are crucial at various stages of the food production process. Computer vision technology can automate these tasks, eliminating bottlenecks and ensuring smooth operations.

Benefits for Production Processes:

Real-Time Monitoring: Continuously monitor production lines. CV systems provide real-time analysis of products, detecting issues instantly and preventing faulty products from advancing through the production process.

Batch Consistency: Ensure uniformity across batches. Automated inspections help maintain consistency in product size, shape, and appearance, crucial for brand reputation and customer satisfaction.

Waste Reduction: Minimize product wastage. By accurately detecting defects early, manufacturers can reduce waste and improve resource utilization.

By integrating computer vision into production processes, manufacturers can achieve higher efficiency, lower costs, and better product consistency.

Enhancing Food Safety with AI-Driven Insights

Food safety is a critical concern for manufacturers. Computer vision can play a vital role in enhancing safety measures and ensuring compliance with regulatory standards.

Benefits for Food Safety:

Contamination Detection: Identify contaminants quickly. CV systems can detect foreign objects and contaminants in food products, ensuring safety and compliance with food safety regulations.

Regulatory Compliance: Maintain adherence to safety standards. Automated inspections help manufacturers meet stringent regulatory requirements by providing detailed records and traceability.

Predictive Maintenance: Anticipate equipment failures. CV technology can monitor equipment conditions and predict maintenance needs, reducing downtime and preventing potential safety hazards.

These advancements ensure that food manufacturers can maintain the highest safety standards, protecting consumers and their brand reputation.

Optimizing Operations with Computer Vision

For food manufacturers, optimizing operations is key to staying competitive. Computer vision offers a range of tools to enhance operational efficiency and productivity.

Benefits for Operations:

Process Optimization: Identify inefficiencies and optimize workflows. CV systems provide detailed analytics on production processes, helping manufacturers streamline operations and reduce bottlenecks.

Enhanced Decision Making: Make data-driven decisions. Real-time insights from CV technology enable managers to make informed decisions, improving overall operational efficiency.

Cost Savings: Reduce operational costs. By automating visual inspections and optimizing processes, manufacturers can significantly cut labor and production costs.

These benefits allow manufacturers to enhance productivity, reduce costs, and improve overall operational efficiency.

Dive into the Future with ezML

At ezML, we specialize in integrating computer vision solutions seamlessly and cost-effectively for various industries, including food manufacturing. Our expertise in serverless computer vision infrastructure, zero-shot learning models, and optimized infrastructure makes us the ideal partner for manufacturers looking to revolutionize their operations.

Why Choose ezML?

Seamless Integration: Easy-to-implement solutions that integrate with existing production systems.

Cost-Effective: Affordable technology for all scales of operations.

Expertise: Proven track record in computer vision technology and pioneering AI use cases.

Ready to transform your food manufacturing operations with computer vision? Schedule a meeting with ezML to explore how we can free up visual task bottlenecks and directly boost efficiency for your operations at https://calendly.com/ezml/consultation.

By embracing computer vision, the food manufacturing industry can unlock unprecedented levels of quality, efficiency, and safety. Whether you're aiming to enhance product quality, streamline production processes, or ensure food safety, computer vision offers the tools you need to succeed. Dive into the future of food quality inspection with ezML.